Testimonial – Motor yacht “Sanam” – Ultraguard Success

Yachtprojects are happy to announce that the first season of the Motor yacht “Sanam” has been a very successful on many fronts, including the results from the installation of the Ultra Guard antifoul system.

Donovan, the Chief Engineer, sent us in some photos of the main sea suctions which as you can see are Barnacle free and his comments attached are “ During the past 5 years and in a normal season on this vessel we have had to clean out the main sea suctions at least twice if not more for shell growth, Since the installation of UltraGuard I have kept the same schedule of inspections and this photo is month 4. No shell growth and very minimal surface weed. Our air-conditioning cooling system by this stage of any season is being treated with Barnacle Buster or similar and again since fitting of Ultra Guard there is zero growth in the coolers.

Ultraguard Ultrasonic Antifouling

Designed, developed and manufactured in the UK by Marine Growth Prevention Specialists Ltd (MGPS)

Ultraguards Advanced Ultrasonic antifouling solutions can be customised to suit your vessel’s requirements.

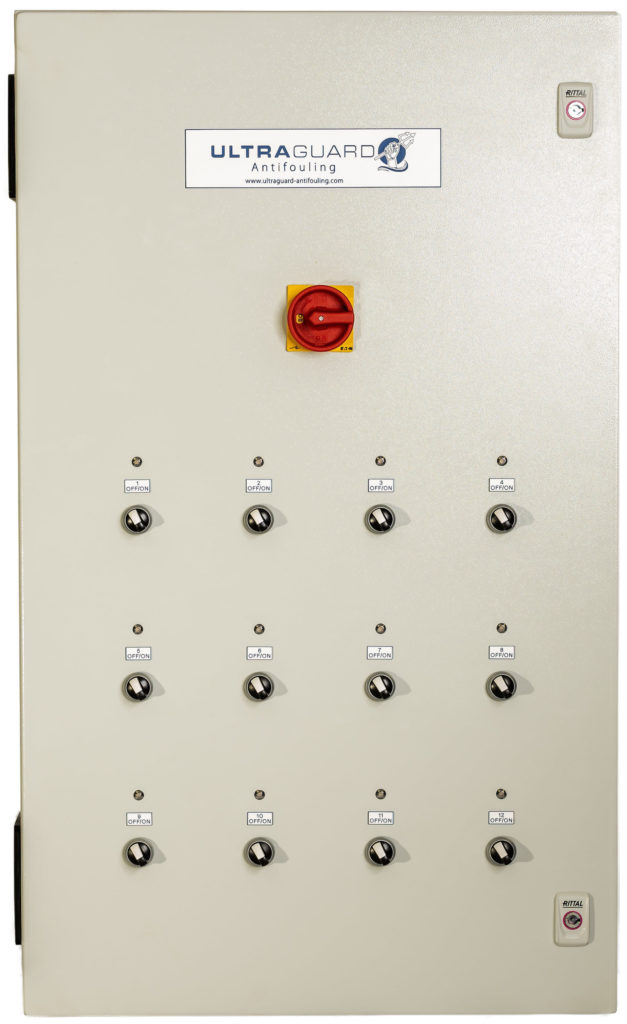

Ultra Guards Digital Control circuitry and the choice of 4 types of transducers to ensure your vessel receives the antifouling profile it requires.

Bespokely designed to suit each vessel you can be sure that your system will suit your vessel

What makes us different

Research – Having been in the UAS market with other brands for five years, Ultraguard have witnessed and been involved with a lot of the research that’s been done over the years. They’ve also carried out a lot themselves. They’ve also had the benefit of seeing what research theories work in the real world on other systems and what doesn’t. All of this has been implemented into Ultraguard.

Quality – They like to think that Ultraguard has the highest quality of component and manufacturing in the market. Their factory is fully ISO compliant and have full traceability on every component used right back to who signed the purchase order at the suppliers. And because their factory is in the UK and not a remote factory in the Far East, they’re able to very quickly fix issues that do arise.

Power – Ultraguard is the most powerful system on the market. The acoustic waves are up to ten times as powerful as some competitors. They’ve optimised their circuitry and amplifiers to work with their transducers. This gives a cleaner and more powerful signal. They even went as far as having their transformers custom wound in the UK. Doing this instead of using off the shelf transformers has allowed them to lower operating temps by 20%. This leads to

less losses and better reliability.

Environmentally Friendly

Ultraguard Antifouling is a zero pollution system. No chemicals, metals or poisons enter the marine eco system.

No Disturbance

Ultraguard’s operation doesn’t disturb marine mammals.

Cost Effective

With no consumable parts and ease of installation, Ultraguard can give an immediate return on investment and pay for itself many times over during the vessel’s life.

Easy Installation

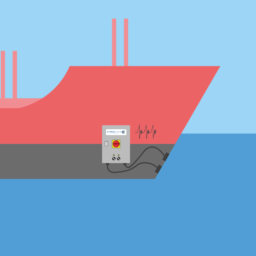

Ultraguard can be easily fitted to any vessel. The transducers require no cutting or welding to fit and Ultraguard can be fitted whilst the vessel is at sea. No need to dry dock!

Less Downtime

Keeping cooling systems and hulls free of marine growth improves efficiency and reduces downtime.

Microbial Control

Ultraguard is effective at combatting Diesel Bug in Marine Gas Oil and Diesel tanks.

Copper pollution from ICAF antifouling anodes is adding dramatically to all of the pollutions.

Ultraguard Antifouling offers vessel owners a cost-effective, ZERO pollution alternative.

EU’s memorandum

The EU’s moratorium on the outlawing of copper based biocides ends on the 31st of December 2025. After this date the use of copper based antifouling on vessels, such as Impressed Current Antifouling Anodes (ICAF) in EU waters will be banned. Fitting Ultraguard now will ensure your vessels comply with future regulations.

The water contains a microbiome of various species of larvae in suspension that will attach themselves to marine structures and surfaces if the conditions allow. These larvae require a number of environmental criteria to be in an optimum state to allow them to begin the colonisation process. These criteria include water temperature, salinity, light levels, time of year, concentration of larvae and seed in the water. These along with other criteria can affect colonisation depending on the species and type of growth. A suitable surface to attach to is also essential.

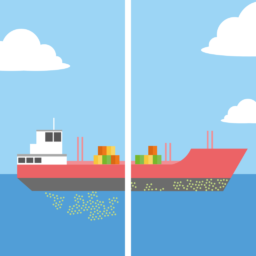

Our goal is to use ultrasonic sound waves to create a resonance in the structure which causes a vibration in the surface being protected. This, in turn, becomes a sub-optimal location for the colonisation process to begin. This vibration can only prevent the colonisation at the larval stage. Mature growth creates bonds that are too strong to be affected by the vibrations. To this end, ultrasonic antifouling systems can only keep a clean surface clean, they can not clean a heavily fouled surface.

It sounds like a simple process but acoustically there are many challenges to overcome, especially on complex structures such as coolers. It is the research and development that we and our partners have undertaken that sets us apart from the competition.

In the control panel, each transducer has its own control board and power supply. These generate ultrasonic acoustic signals which are then boosted via an amplifier and sent down the cable to the transducer. The transducer is attached to the structure being protected by an adhesive bond. It is essential that there is always full surface to surface contact between the transducer head and the protected structure. This is why we choose the bonding method over methods such as a screw in mounting ring, welded or attached to the surface. In that method the ultrasonic waves can loosen the transducer in the mounting ring.

By causing each transducer to resonate at the correct frequency we induce the required vibrations which prevent the larvae from attaching themselves to the surface being protected.

Ultraguard’s design means that if a transducer cable, power supply or control PCB is damaged or fails it can be swapped out by ship’s staff in a matter of minutes. The rest of the system can operate as normal until the replacement takes place so there is minimum downtime and minimum loss of antifouling effect

How it works!

The seas and waterways contain a suspended microbiome of larvae and seed which will become marine growth.

To colonise and grow these larvae require the correct conditions. Sunlight, salinity, water current and temperature all require to be at optimum levels.

If all the criteria are correct and there is a suitable stable surface to attach themselves to, the larvae will colonise that surface and start to develop into marine growth.

Ultraguard Antifouling uses pulses of ultrasonic sound at specific frequencies to induce a resonance response in the surface to be protected. This causes the surface to vibrate.

By causing the protected surface to vibrate slightly at the correct frequencies, Ultraguard creates a sub optimal environment, which, prevents the larvae from attaching to and colonising the surface.

Keeping a ship’s hull free of marine growth in this manner drastically reduces drag on the hull. This reduces fuel consumption, greenhouse gas emissions and ultimately reduces the vessel’s operating costs.